As lead times for many electronic components loosen, it may be tempting to worry less about the problem of counterfeit components. At the same time, the realities of an increasing number of end-of-life components and an ever-shifting blend of component manufacturing mixes, especially in the semiconductor market, remains. In short, counterfeiters aren’t going anywhere –and buyers need to continue to be vigilant.

Measuring the Problem

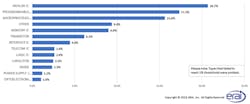

The ERAI, a global information services organization that monitors, investigates and reports issues affecting the global electronics supply chain, has tracked the cycle of counterfeiting over decades and it has waxed and waned. Currently, bad actors creating fake components are on an upswing. In 2022, ERAI reported a total of 768 suspect counterfeit and nonconforming parts, an increase of 35% in the number of reported parts from 2021 to 2022. Global semiconductor sales remained flat during the same time, indicating that the increase is significant.

It’s not all bad news, though. Although analog ICs, programmable logic ICs and microprocessor ICs remain the most targeted component types, accounting for more than a half of all reported component types, counterfeit capacitors have dissipated (perhaps due to increased availability of these components).

Smart and Getting Smarter

In the past, counterfeiter’s efforts were clumsy at best. For example, they might take one part and put a different blacktop on it to make it look like a rarer or more expensive part. You would see re-claimed parts being passed off as new, or standard commercial parts being sold as industrial grade. It was a “take the money and run” strategy, where customers didn't recognize the problem until after they paid for the parts.

Now, it is nearly impossible to spot the difference between some counterfeits and the real thing. Further, as noted above, there are more fake components in the product stream. About 80% of parts reported as counterfeit were new occurrences, according to the ERAI. That indicates that the array of counterfeit components being created is quite broad. Further, about one third were classified as obsolete or not for new design (NFND), another indication that the breadth of counterfeiters is spreading.

Recent research from the University of Florida points to the potential disastrous effects of using counterfeit parts, including:

• Security and reliability risks for critical systems and infrastructure

• Substantial economic losses for intellectual property owners

• Revenue for bad actors that, in turn, threatens other aspects of society

• The reduction of incentives to develop new products and ideas

At times, the problem arises before the time of order, leading to financial losses. In 2021, 101 wire fraud cases were reported to the ERAI up from 70 in 2020 and 17 in 2016. In this scenario, shady brokers offer to sell needed parts and then, after the buyer transfers funds for the goods, they never get delivered.

Getting Ahead of the Curve

The best way to mitigate these risks is to work only through authorized or franchised partners. Business realities, though, may make that option impossible. There are a handful of additional ways to reduce the risk of buying fakes.

1) Build trust up front. Building good relationships with suppliers isn’t old-fashioned. It’s just good business. Every time you pick up the phone, it builds trust. Emails can confuse things or get lost – they are better as a follow-up to a phone call. Knowing your suppliers is perhaps the first and foremost way to reduce counterfeiting, and these relationships can’t be built over email. In addition, check in regularly with your in-house engineers. By building a collaborative relationship you may be able to manage hard-to-find part scenarios in the design stage rather than later.

2) Stay in touch with counterfeiting standards. The electronics industry has collaborated to create a number of standards to reduce the risk of counterfeit parts. By understanding the scope and focus of these different standards, an organization can integrate avoidance and mitigation of counterfeits throughout their process. There are currently more than two dozen that address various industries and areas of the supply chain. When you work with a distributor, these standards can help you decide what testing or other mitigation efforts you might want.

3) Carefully consider your company’s contracts. Familiarize yourself with the terms and conditions of your organization’s contracts. Too often, a standard contract includes language in terms of specific parameters (such as asking that a part not be more than 18 months old, even though that part was end-of-life (EOL) four years before that). These specifics make sense for newer parts but may not be reasonable for a hard-to-find part. Lack of awareness around your own policy and procedures can make your suppliers and customers wonder what other standards and requirements are slipping through the cracks.

Counterfeiters are the worst kind of predators – looking for desperate buyers who are willing to take shortcuts. It’s worth the effort to go the extra mile and stick with known, authorized partners. The cost of counterfeit mistakes is too high.